Air Force /

F35 Maintenance

Checkout the official Air Force demo video

Redesigning Flight-Line Maintenance

The Problem

The Autonomic Logistics Information System (ALIS) is a slow, confusing, and inaccurate hardware and software system built to be paired with the F-35 Jet.

How bad is it, you say? Here are some quotes to be around the web from the Department of Defense (DoD) community:

“How bad is the F-35’s computerized maintenance system, ALIS? So bad the plane may be better off without it.”

“ALIS’ problems are legion and legendary in the defense acquisition community. New software builds take more than a year to formulate and are often late. Data gaps have caused canceled missions.”

“Nothing about ALIS development mirrored the best practices of the tech community, and the result was “good code in a fairly bad user interface and a bad architecture.”

TIME

1 Year

MY ROLE

Product design

Strategy

Research

The Plan

Team

Objective

The simple and efficient management of

flight-line maintainers.

How We Got There

Field Research

We began with a week-long trip out to Nellis Air Force Base to understand our user’s existing workflows and pain points.

During the project, we conducted bi-weekly zoom calls with our users to further validate our ideas, and took several other research trips to other Bases to ensure our solutions were covering all F-35 Unit’s needs.

Research Artifacts

Key Insights

Problem 1

Problem 2

Problem 3

Result

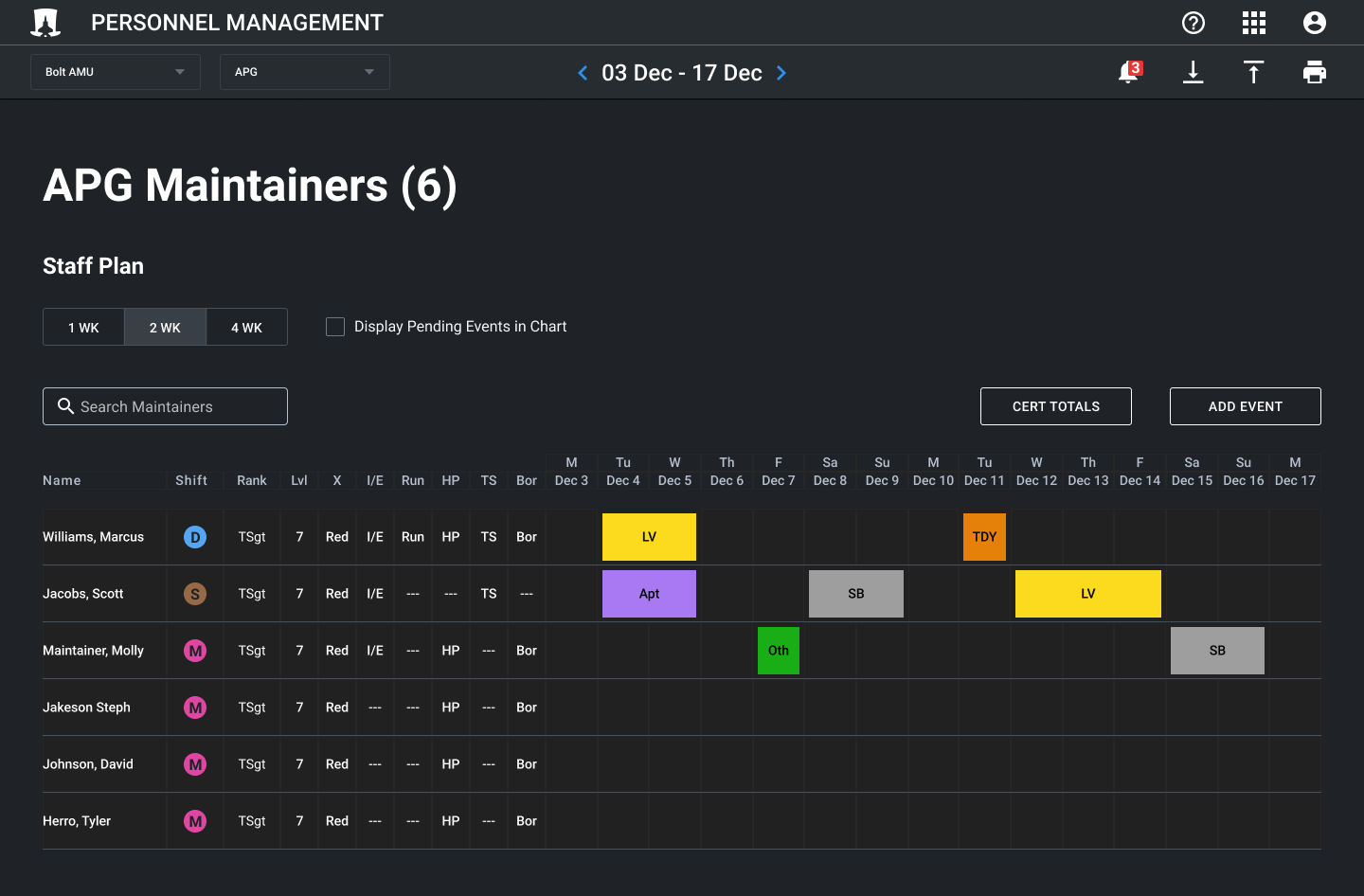

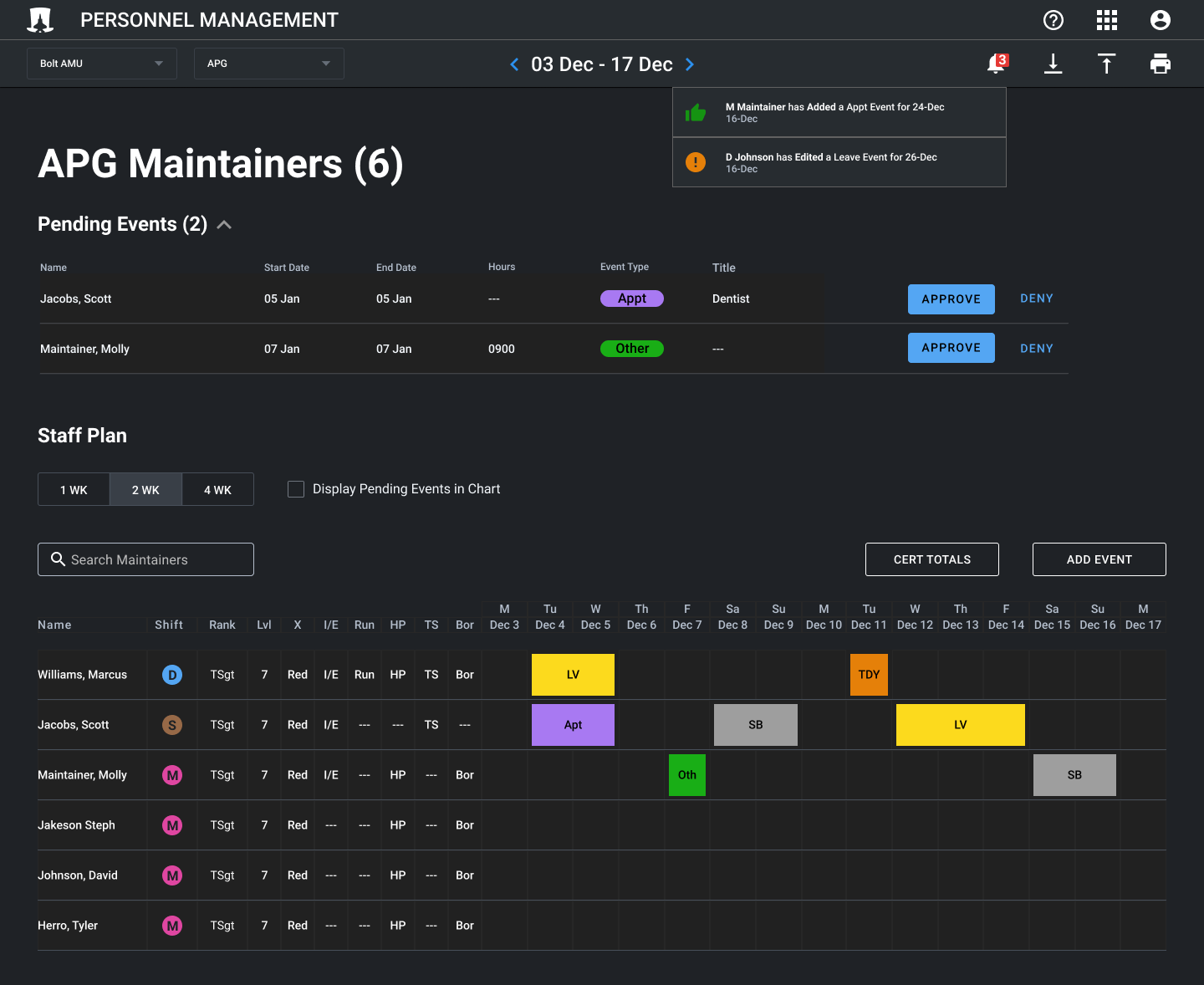

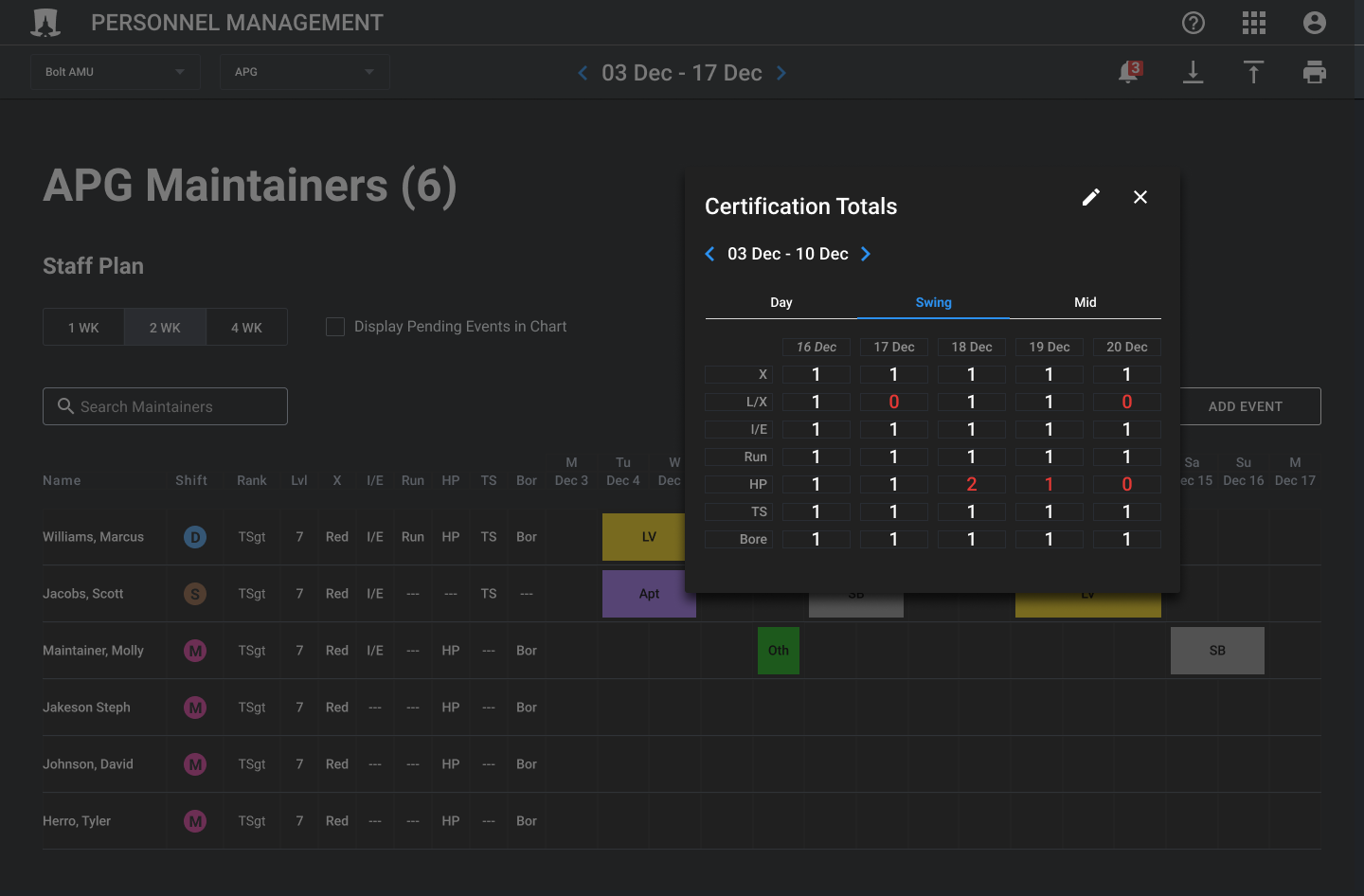

Preview of certification coverage for the upcoming week. Each row represents a certification that a maintainer has been specially trained in.

To complete certain work, it’s required to have a maintainer certified in that work.

Section Chiefs use these certifications as a measurement of their staff health, and whether or not they need to move maintainers around, or deny appointments.

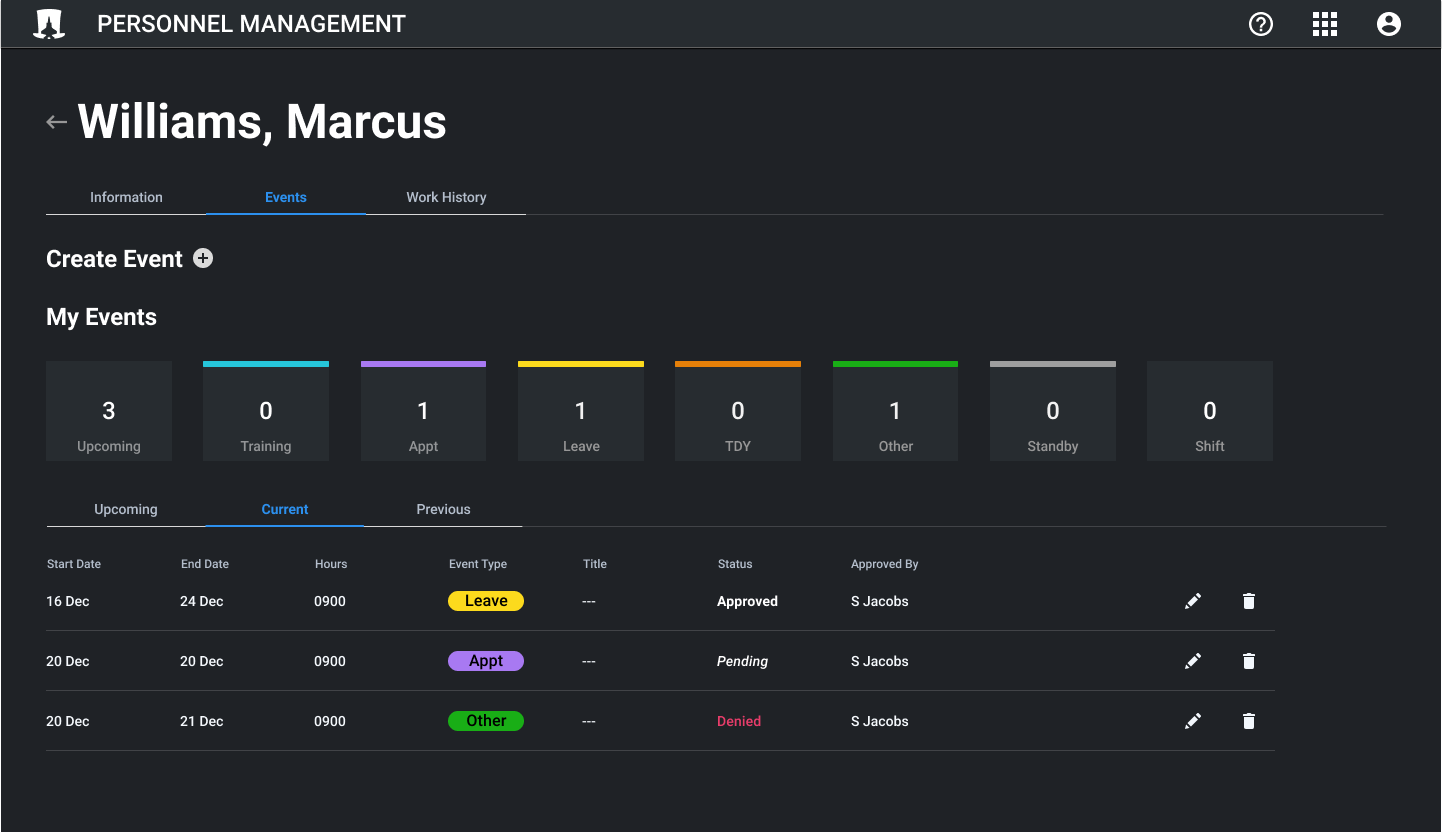

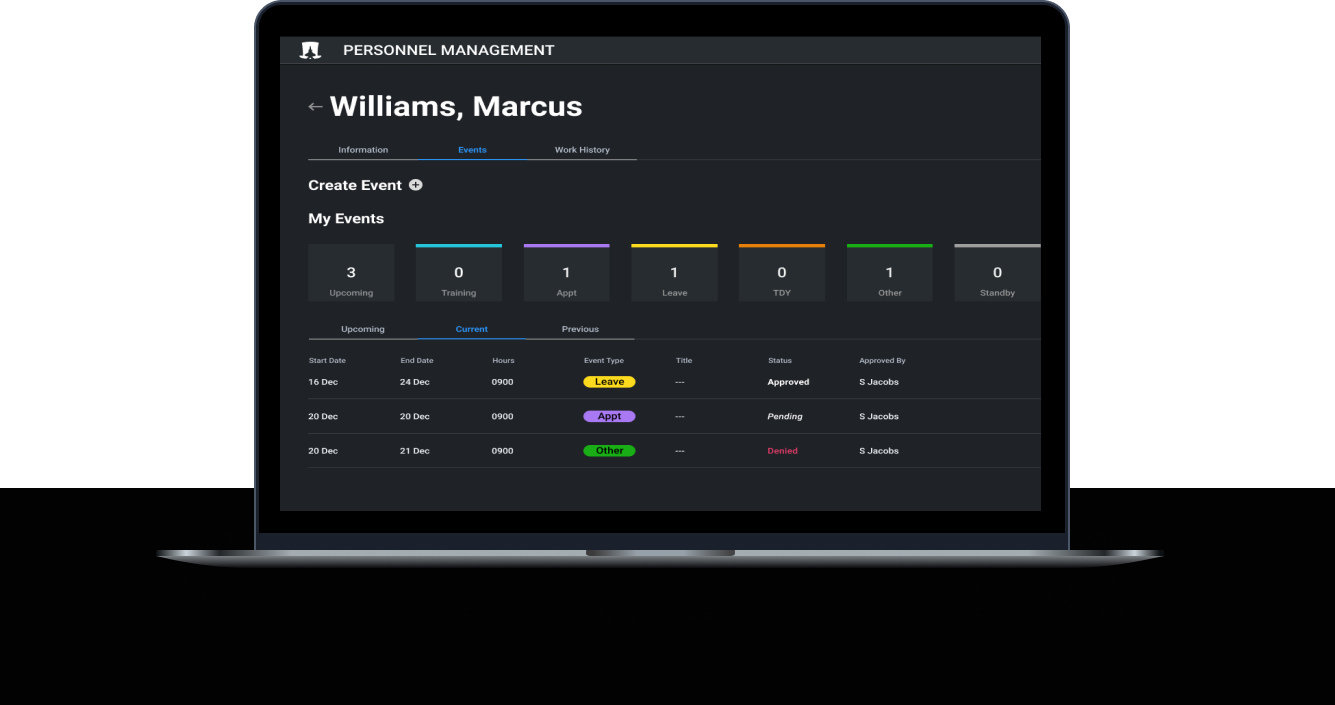

Maintainer’s page, where both they and the Section Chief can add and view appointments, filter by appointment type, and view what type of work they’ve accomplished in the past (still in work).

This previous work history is used to inform Section Chiefs when the maintainers are due for an upgrade to a new level.